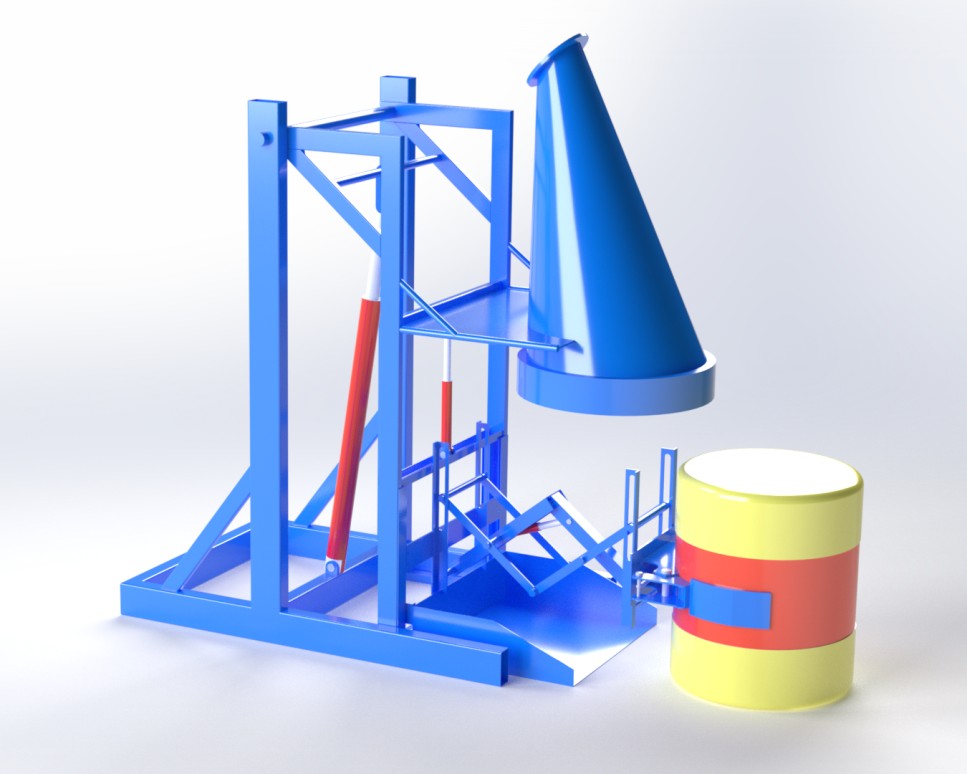

Fully Enclosed Drum Discharge Station

Features and Benefits:

z Packaging bag in the drum is opened in a sealed environment

z Customized drum dischargers can safely unload materials into a variety of processing equipments

z exclusive Lift & Seal System seals the drum to a closed pour hood to prevent contaminants from entering the process

z Pour cone includes fluidizers, a pneumatic turbine vibrator, and a slide gate with a stainless steel discharge nozzle.

z Rotation System inverts drum for maximum product discharge

z Hydraulic system for reliable operation. Includes a fan driven hyydraulic fluid heat exchanger and a temperature control switch for continuous duty cycle operation.

z ATEX version for dust environment